- Home /

- HVACR SERVICE TOOLS /

- BRAZING /

- FLUX FOR SILVER BRAZING 200g

Shop Now

-

HVACR SPARES & EQUIPMENT

- ACTRONAIR & CONTROLS

- EVCO CONTROLS

- EMERSON/COPELAND

- COMMERCIAL KITCHEN VENTILATION

- EVAPORATORS

- CONDENSING UNITS

- CONDENSERS

- BITZER

- EMBRACO

- AIREF

- FRASCOLD

- DANFOSS

- SANHUA

- RANCO CONTROLS

- REGAL

- AXIAL FANS, MOTORS & BLADES

- SYSTEM COMPONENTS

- COMMERCIAL COMPRESSORS

- CONTROLS

- DEFROST CONTROLS

- SKOPE

- KULTHORN KIRBY

- REFRIGERATION HARDWARE

- HVAC+R EQUIPMENT & SPARE PARTS

-

HVACR SERVICE TOOLS

- SUPERCOOL HVACR

- RECLAIM UNITS

- VACUUM PUMPS

- LEAK DETECTORS

- REFRIGERANT SCALES

- MANIFOLDS, GAUGES & HOSES

- REGULATORS

- OXY SETS/BRAZING TORCHES/ETC

- DISPOSABLE BOTTLES

- BRAZING

- UV DETECTION/INJECTION KITS

- CHEMICALS

- SUPER SEAL/CLIPLIGHT

- REPAIR PATCHES

- TOUGH TOOL BAGS, VETO PRO PAC

- THERMOMETERS

- HAND TOOLS

- TEST & MEASUREMENT

- GENERAL HVACR TOOLS

- TAPES/GLUES/PAINTS/ACCS'/ETC

- FIRE EXTINGUISHERS

- ADAPTORS & ACCESSORIES

- MISCELLANEOUS

- BLACK DIAMOND TOOLS

- REFRIGERANT & EMPTY CYLINDERS

- COPPER PIPE & FITTINGS

-

AIR CONDITIONING

- AC SYSTEMS

- A SAUERMANN PUMPS

- ASPEN PUMPS

- HANWEST CONTROLS

- BIG FOOT SUPPORT SYSTEMS

- CONDENSATE PUMPS

- AIR CONDITIONING FILTERS

- WALL & ROOF BRACKETS

- PVC/PLASTIC DUCT & FITTINGS

- DRAIN PIPE & ACCESSORIES

- MOUNTING FEET & SLABS

- AIR DIFFUSERS & FLEXIBLE DUCTS

- A/C INSTALLATION ACCESSORIES

- COLOURBOND TRUNKING

- UNIVERSAL REMOTES

- THERMOSTATS

- GLYCOL

- TESTO EQUIPMENT

- MECHANICAL SERVICE EQUIPMENT

- ELECTRICAL COMPONENTS

- AUTOMOTIVE

- DOMESTIC REFRIGERATION

-

HEATING SPARES & EQUIPMENT

- BAIN MARIE EQUIPMENT

- HOT WATER SPARE PARTS

-

STOVE/OVEN/GRILL SPARE PARTS

- FAN MOTORS & ACCESSORIES

- THIN COIL ELEMENTS

- MONOTUBE ELEMENTS

- SOLID HOTPLATES

- UNDERGLASS HILIGHT ELEMENTS

- OVEN FAN FORCED ELEMENTS

- OVEN &/OR GRILL ELEMENTS

- BOWLS & PANS

- RINGS & SOCKETS

- DOOR HINGES

- THERMOSTATS

- CONTROLS

- SWITCHES & INDICATORS

- TERMINALS & CONNECTORS

- OVEN KNOBS, CABLES & SEALS ETC

- GAS COOKTOP SPECIFIC PARTS

- MISCELLANEOUS

- EGO

- WATER FITTINGS & ACCESSORIES

- CAPACITORS

-

GENERAL APPLIANCE SPARES

- DISHWASHER PARTS

- DOOR INTERLOCKS

- DRYER PARTS

- FISHER & PAYKEL PARTS

- GE PARTS

- HOOVER PARTS

- HOOVER TWIN TUB

- HOSES, CLAMPS, CONNECTORS ETC.

- KLEENMAID PARTS

- LG PARTS

- MAYTAG PARTS

- MOTOR BRUSHES

- SIMPSON PARTS

- UNIVERSAL BEARINGS

- UNIVERSAL PARTS & ACCESSORIES

- V, DRUM & BLOWER BELTS

- WHIRLPOOL PARTS

- MISCELLANEOUS

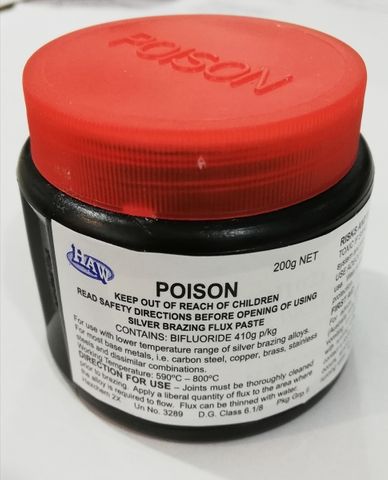

FLUX FOR SILVER BRAZING 200g

Stock Code:

RF032

Regular Price: $62.43 (inc GST)

Regular Price:

$62.43 (inc GST)

Price:

$36.10 (inc GST)

Quantity Breaks

1+

$36.10 (inc GST)

Details

-

In Stock Unit:Each

Description

HARRIS Stay-Silv® White Flux All-purpose White Brazing Flux 40021

An all-purpose, low-temperature flux for use in silver brazing. Use with most ferrous and non ferrous metals, not recommended on aluminum, magnesium, and titanium.

Typical Application: Use Stay-Silv White Brazing Flux on applications requiring normal heat. For use with silver brazing alloys on all metals other than aluminum, magnesium, or titanium.

DESCRIPTION: Stay Silv white paste flux is a homogenous brazing flux ideally suited for use with a variety of base metals. A mixture of boric acid and fluoride compounds, it is formulated to provide smooth flux application, even coverage, and excellent protection during braze heating cycles. Stay Silv white flux is recommended for brazing copper and copper alloys, (except aluminum bronze), steel, stainless steel, nickel alloys and other ferrous base metals. It is used with many high silver brazing filler metals of the AWS A5.8 BAg classifications and ISO 17672 class Ag alloys. It is also suitable for use with many phosphorus-copper-silver alloys, (AWS BCuP and ISO CuP), for brazing copper to brass. Flux may be water thinned but care should be taken to avoid excess dilution. Flux turns clear, (transparent), close to brazing application temperature. This is a useful indicator you are ready to apply braze wire or rod.

ACTIVITY RANGE: 1050 – 1600°F (565 - 870°C)

FLUX REMOVAL: Post braze flux residue should be removed to avoid potential corrosion. A hot water wash and brushing with a rag or non-woven abrasive pad, (e.g. Scotch-Brite™), is often sufficient. Additional measures include mechanical cleaning with a wire brush, steam jet, or abrasive blasting media such as grit, soda, or dry ice. Production post-braze cleaning can also be accomplished with proprietary chemical formulas such as Bernite® 45 available from Harris Products Group. This approach is suitable where parts lend themselves to a water bath/tank immersion.

KNOWN ALTERNATIVE PART NUMBERS, APPLICATIONS & SUITED MODELS

40021